Business Case to Working Prototype in

4 Months

Design Service

For more than a decade we have been developing industrial products on behalf of other businesses. This experience has enabled us to develop a unique process for accelerating the journey from idea to working product.

Our process begins by establishing a business case for a new product and then working backwards to a technical solution.

During design and development our teams follow a highly systemised design process that accurately guides and accelerates the design journey to a commercially successful product.

Why work with us?

- 100% Customer Owned IP

- Proven process to accelerate time to market

- Service delivery via video anywhere in Australia

Prototype Development Walkthrough

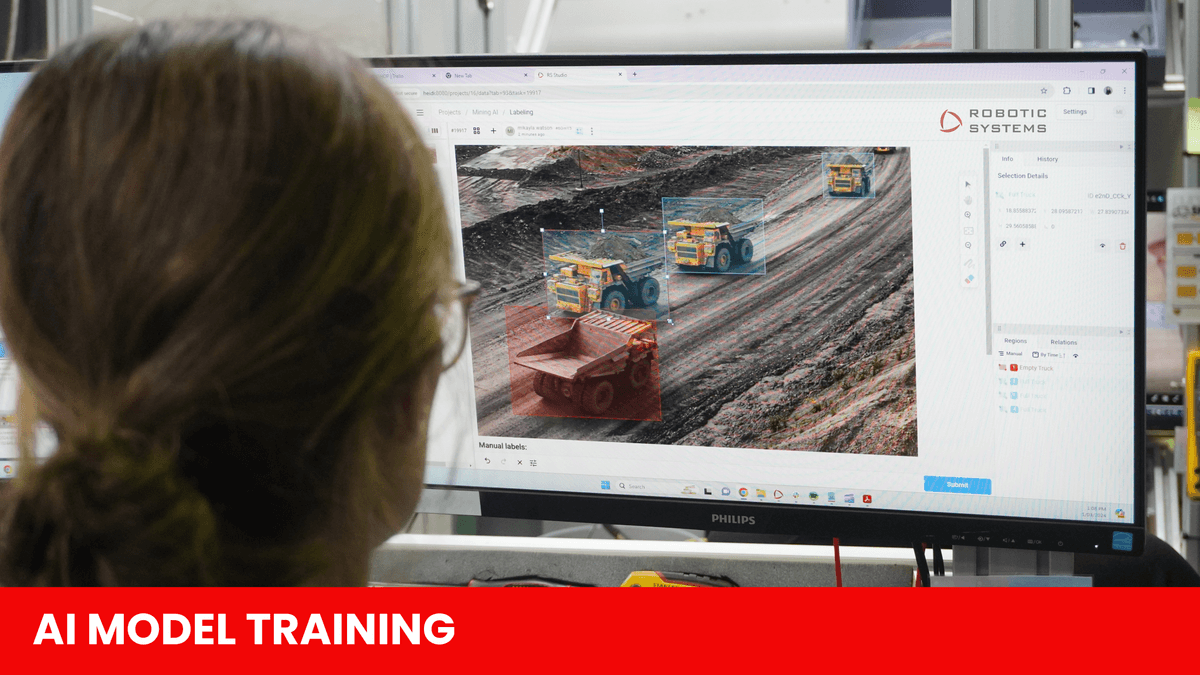

AI Capabilities

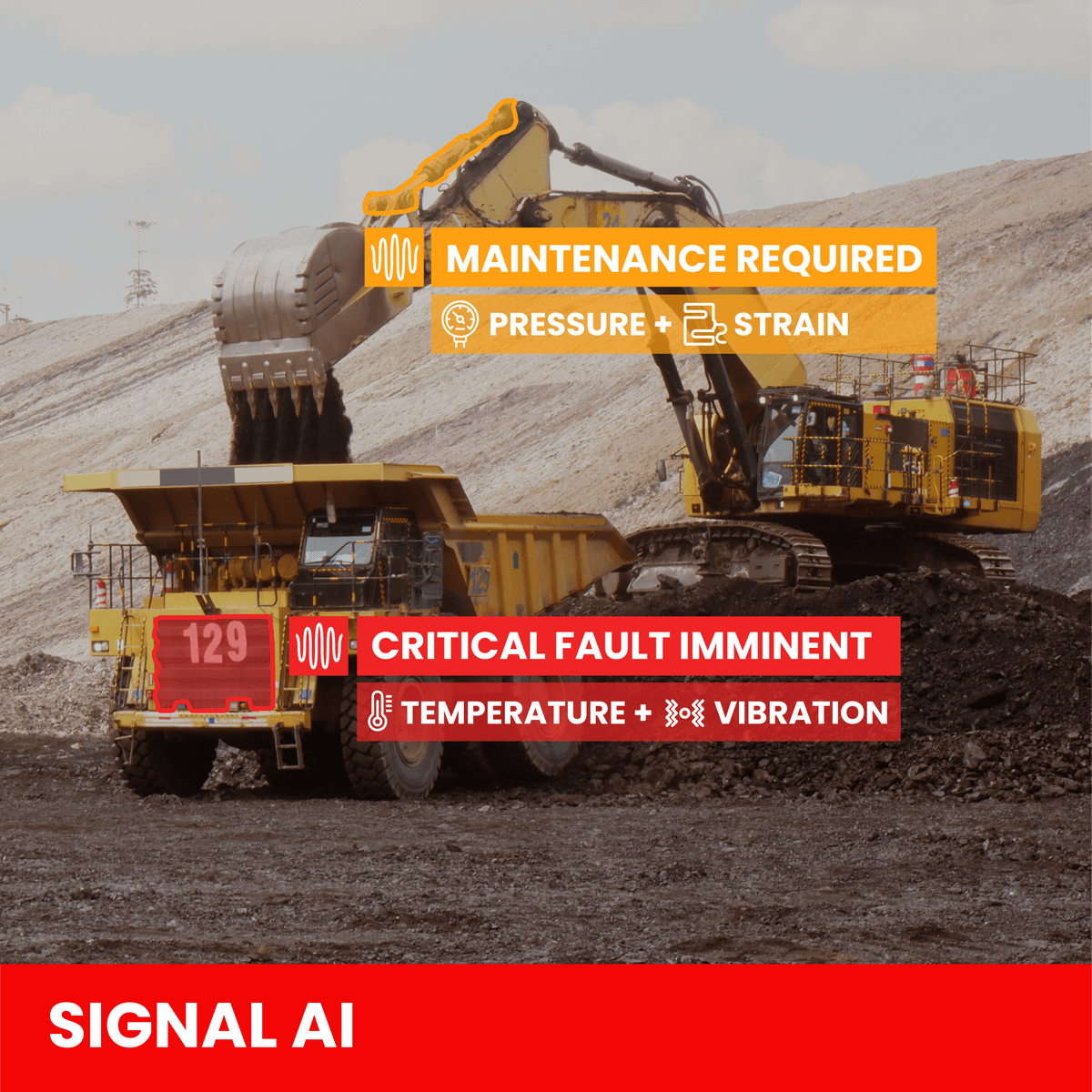

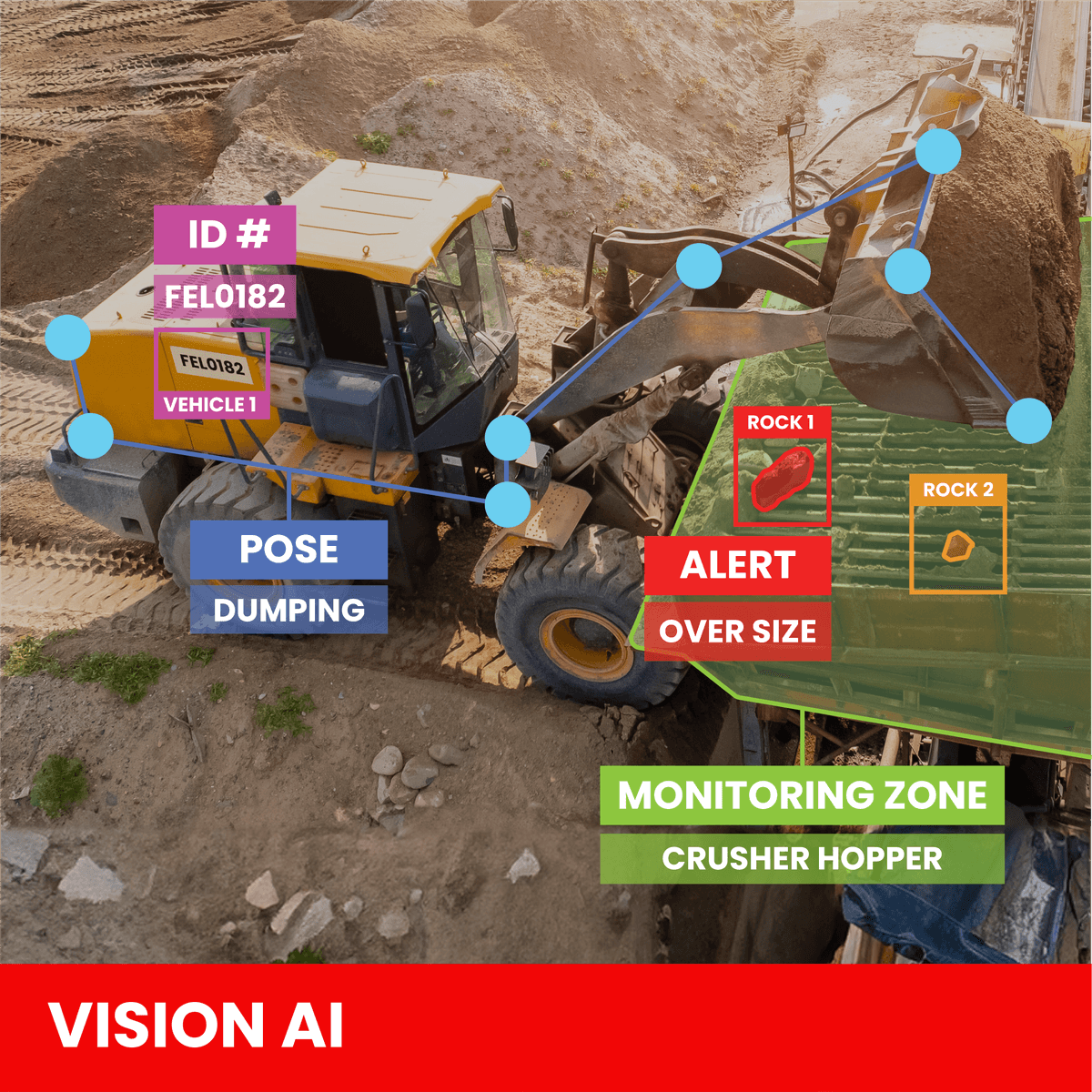

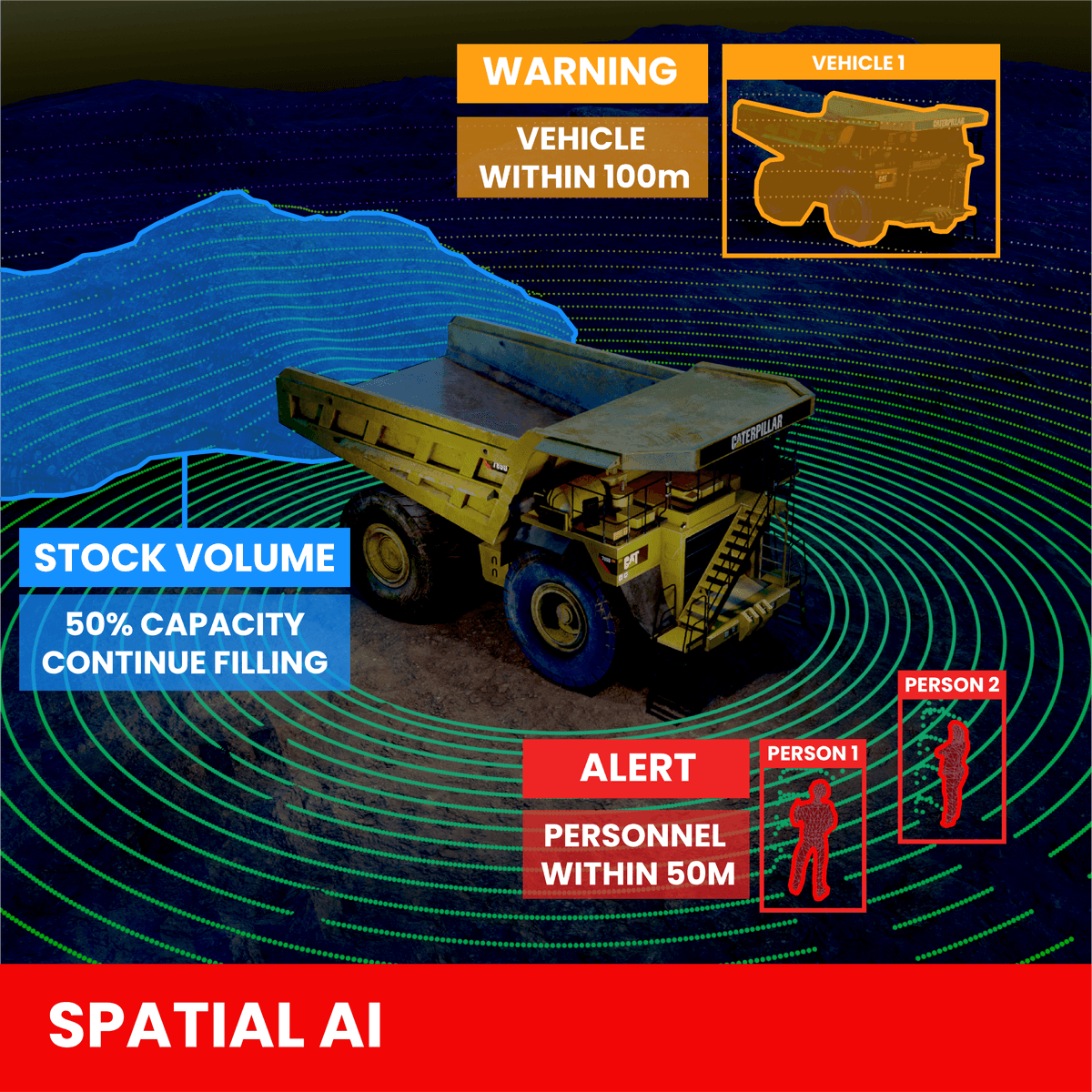

We specialise in developing deep and classical machine learning models to extract highly valuable insights from signals, vision and spatial data on the edge with no cloud dependency.

Sensor types: vibration transducers, IMU, GPS, motion encoders

Example use case: predictive maintenance, fault detection, and system optimisation.

Sensor types: Cameras, Thermal, Multispectral

Example use case: Site monitoring and metric gathering. with defect detection.

Sensor types: RADAR, LIDAR, Magnetic

Example use case: precise volumetric calculation, machine guidance, hazard detection.

Bespoke hardware optimised for power, temperature & vibration requirements of mining

No connectivity requirements

Onsite team and processing hardware for rapid training of models from field collected data.

Electronics

- Custom circuit board design

- Ruggedised design to suit industrial environments

- Radio frequency design and management

- Design for solar & battery power systems

- Integration & synchronisation of industrial sensors

Firmware

- Embedded system firmware development for microcontrollers

- Cloud and customer back-of-house system integration

- Graphical user interfaces for industrial devices

- Data analysis at the edge for industrial applications

Industrial Design

- Market research, form-factor ideation, concepts and business case

- 3D modelling and rendering

- Design for manufacturing procedures optimised for industrial products

Scale your product quickly with our in house manufacturing

Manufacturing

Manufacturing Walkthrough

We have developed and optimised our proprietary manufacturing system specifically for products where changes in the design are frequent and ordering cycles are varied.

Our ISO9001 certified approach uses visual step-by-step video instructions coupled with image based quality control. This provides product owners high repeatability between units as well as tangible traceability to determine the root cause of field faults.

On top of that, we provide warranty and technical support on completed goods which has allowed our customers the reliability to still have working and supported products in the field for more than three years.

Why work with us

- Specialised manufacturing system optimised for low-volume, high-value products

- Warranty and in-field support for all products post manufacture

- Image based quality management system

- Productisation of prototype devices for manufacturing

Certifications

Research Service Provider: #111533

Approved research service provider allowing our customers to claim R&D tax incentives:

- 4007 Control engineering, mechatronics and robotics

- 4008 Electrical engineering

- 4009 Electronics, sensors and digital hardware

- 4017 Mechanical engineering

- 4602 Artificial intelligence

- 4603 Computer vision and multimedia computation

- 4612 Software engineering

- 4611 Machine learning

- 4901 Applied mathematics