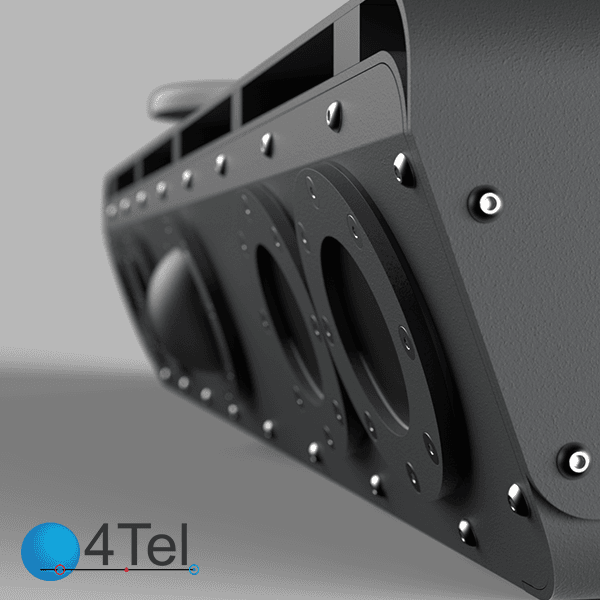

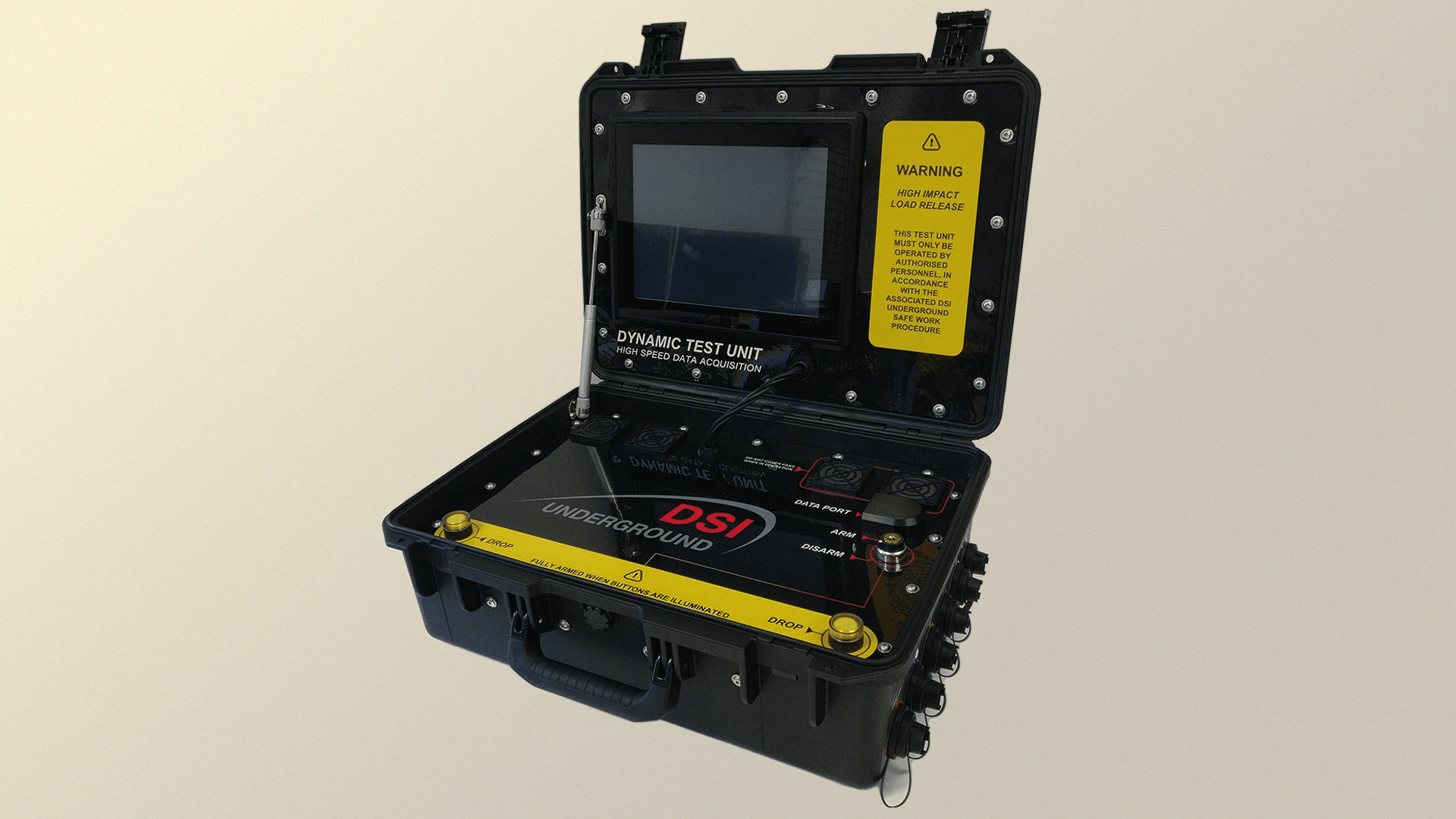

Dynamic Test Unit

Rock bolt performance test system for monitoring forces associated with simulated rock fall events.

Design To Development

3 Months

Target Market

Underground Mining

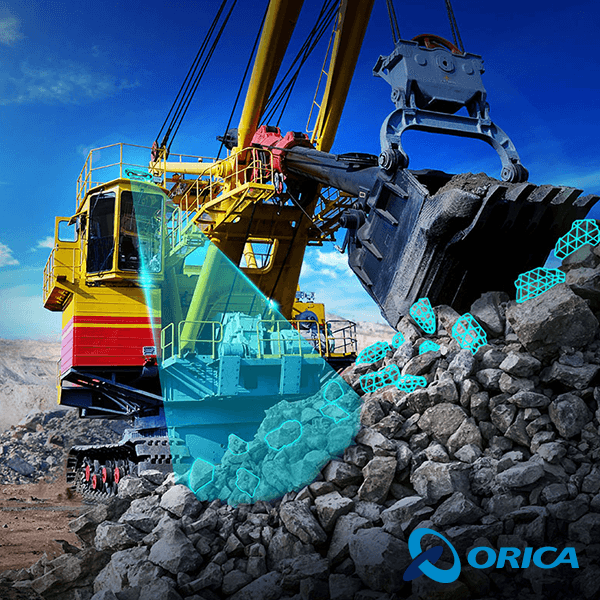

The Customer

DSI Underground is the world’s leading supplier of ground support products, systems and solutions for the underground mining and tunnelling industry. They are present in 70 countries and employ over 2,500 people, including engineers and technical specialists with in-depth experience of the underground industry.

The Problem

Testing the tensile strength of rock bolts is difficult because the forces that the bolt are trying to carry are so large and fast. Because of this, existing industry accepted rock bolt testing facilities rely on very complicated & slow indirect measurement methodologies. This lead to extremely long test lead times for DSI’s product development team who were trying to bring new advanced rock bolt products to market.

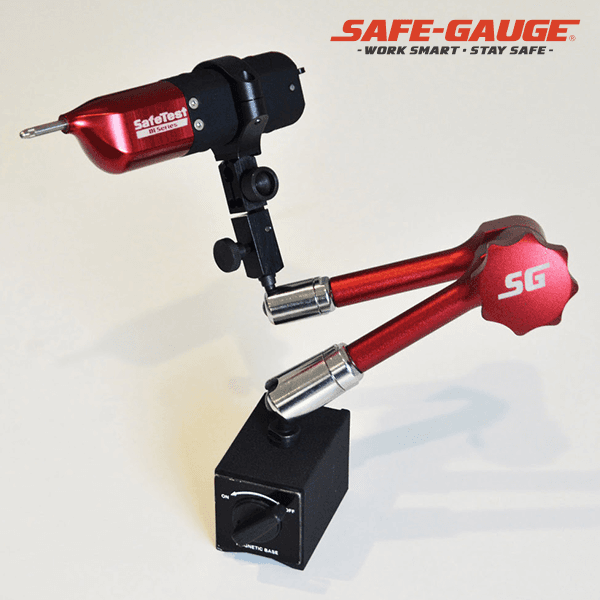

The Technical Solution

Our team of software developers, electrical engineers and industrial designers worked with DSI underground’s technical team to develop a customised tech hardware product with the following features:

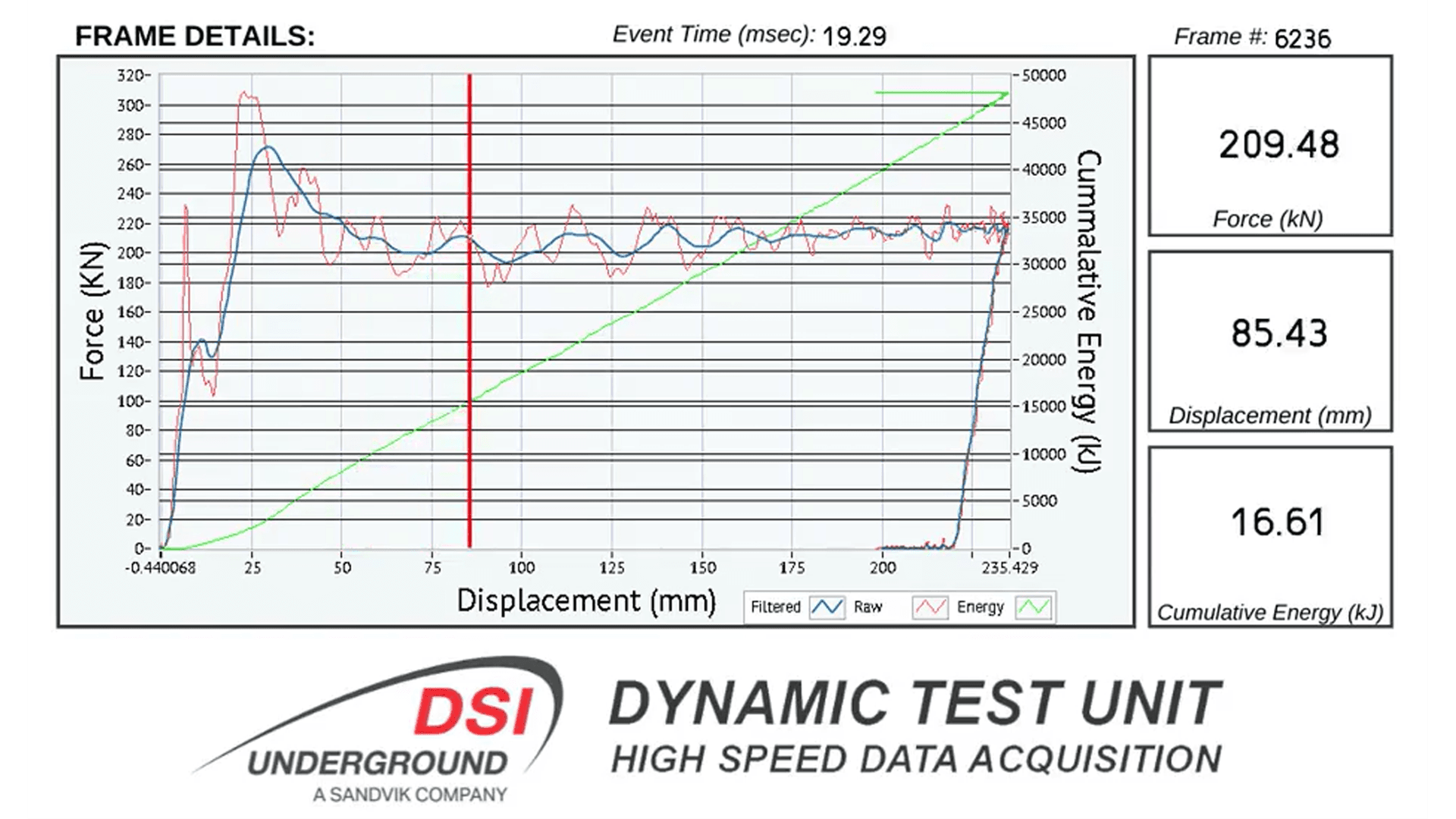

7000 frames per second of high-speed machine vision processing to measure the bolt elongation

200,000 load cell samples per second over 4 channels to measure the subjected force

Precision timing for data fusion between the load cells and images

Automatic generation of easy to understand video and report

The Outcome

This solution gave DSI a way to rapidly accelerate the development cycle of their rock bolts through actionable test data. Since deployment, the Dynamic Test Unit’s accuracy has been verified, making it one of only handful of systems in Australia capable of such measurements. This system has been patented as well published in the proceedings of AUSROCK CONFERENCE 2022. For more information contact DSI Underground.